This portfolio is a reflection of what I have learned and accomplished as a practicing mechanical design engineer, and an engineering student. The portfolio consists of projects ranging from consumer products, medical devices to automotive. Not only do I have experience in CAD and CAE, but also in optimization algorithms, soft machines, machine learning, embedded systems, and PCB designing.

Click on any project to get details

Mechatronics / Electro-Mechanical

Plastic Injection Molded

Academic

Let’s get in touch!

University of Colorado, Boulder

Master of Science in Mechanical Engineering (MSME), Aug 2019 to Dec 2021

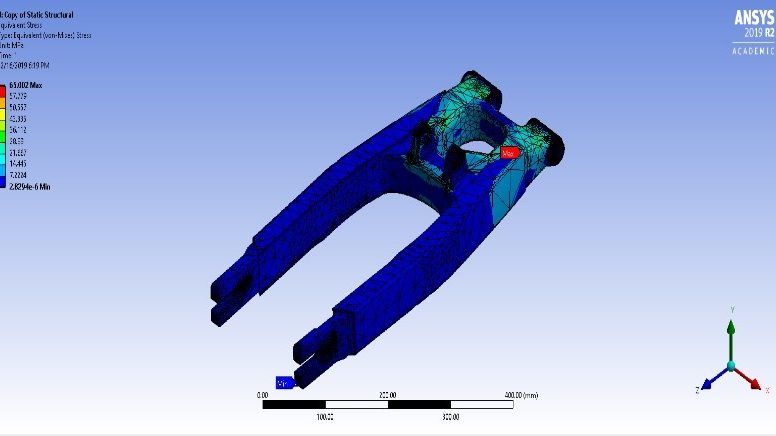

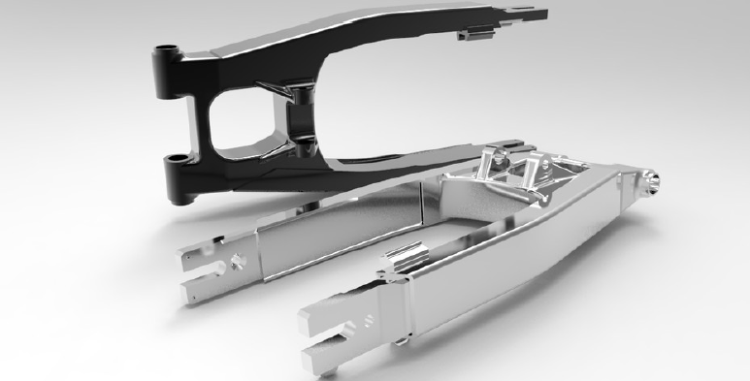

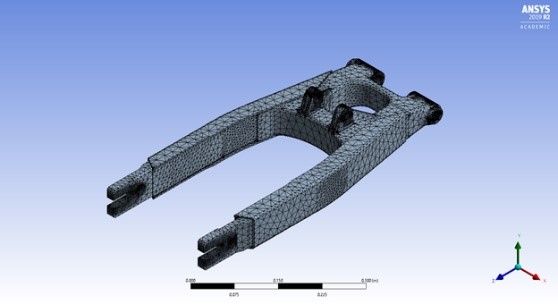

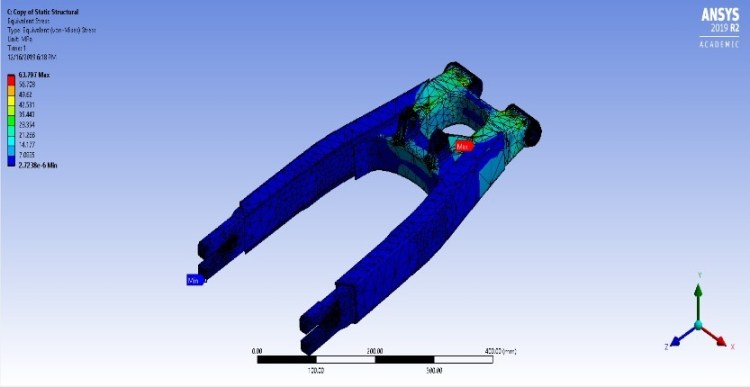

FEA of Honda XR-400 Swingarm and Topology Optimization

Structural analysis was done for 3 different conditions:- Cornering, Braking, and Acceleration along with the weight of a rider. FOS came after optimization to be 5.744 and maximum stress came out to be 87.55Mpa with a reduction of weight of 17%.

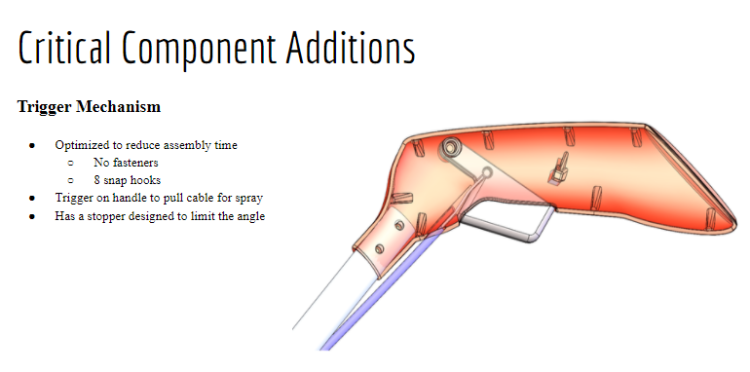

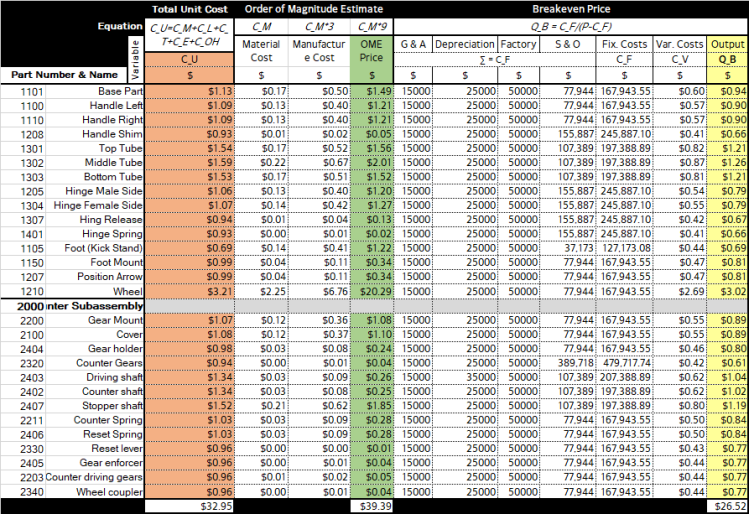

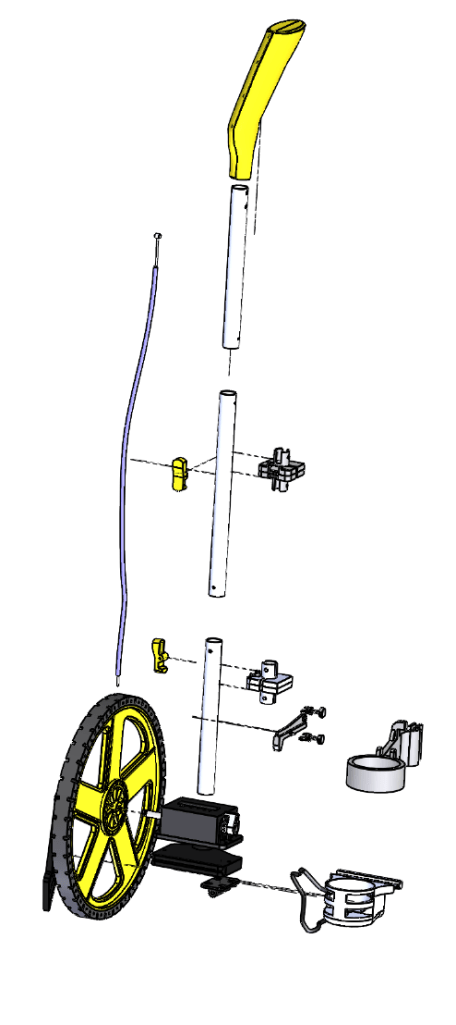

Reverse engineer and Redesign Surveyor’s wheel

Undertook a common construction site tool, reverse engineered the product, and redesigned it to reduce the number of components and price by 14% and adding a spray mechanism all while keeping DFA and DFM tools in mind and without compromising performance, reliability, and aesthetics

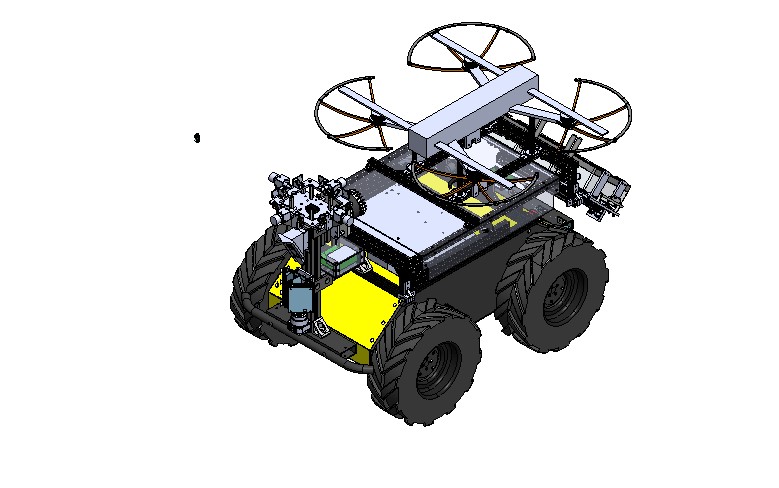

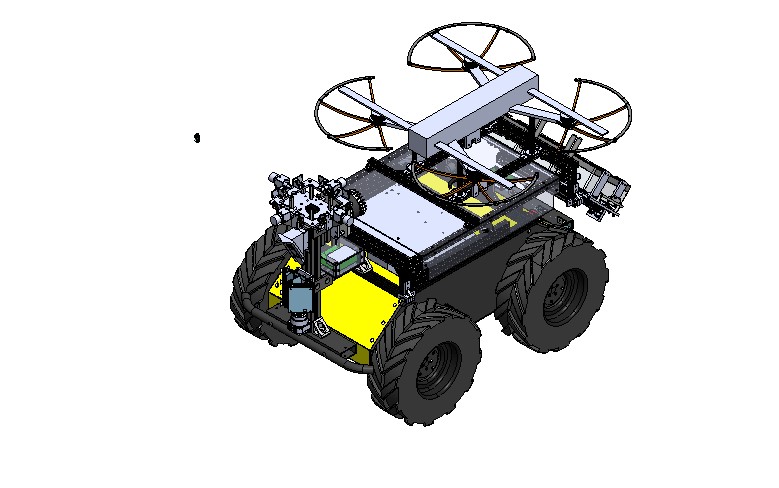

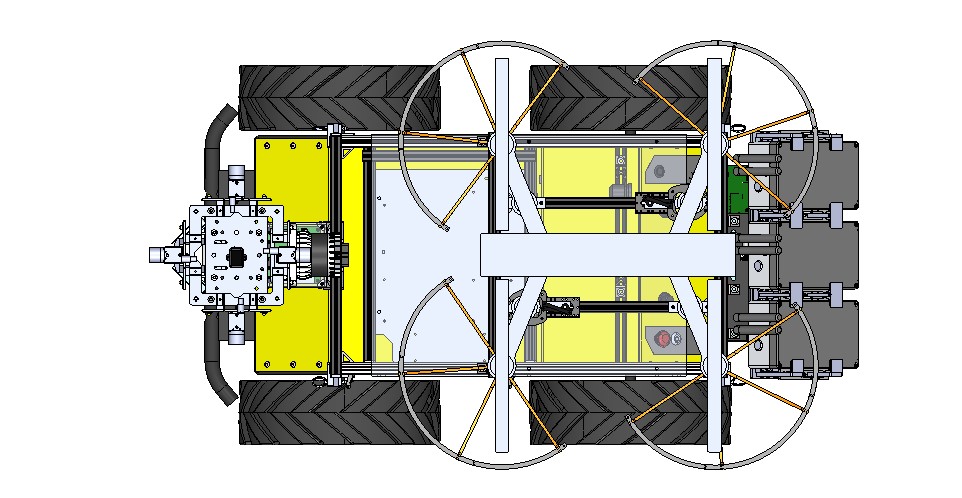

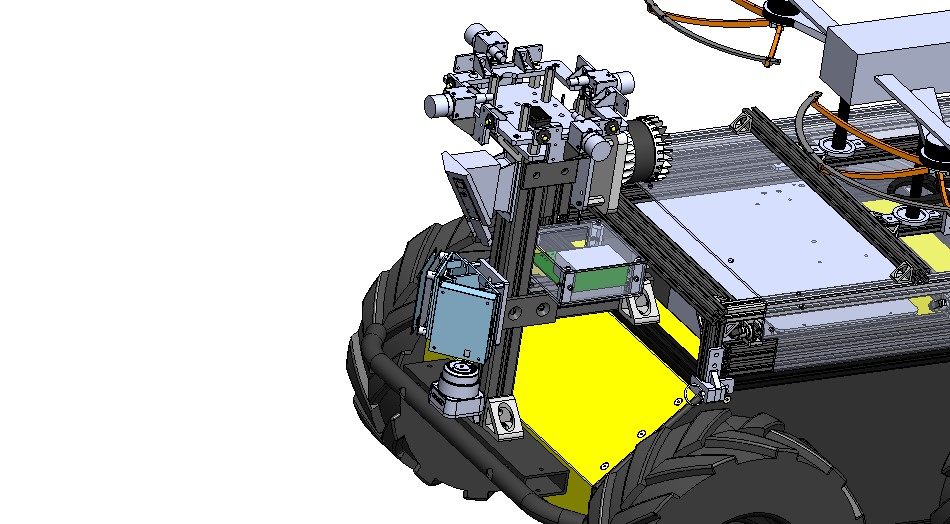

HUSKY ROBOT SENSOR INTEGRATION

Performed sensor integration at Autonomous Robotics and Perception Group, and designed support structure for the LIDAR, RF beacons. Cameras, among other sensors. The original 4wd is Husky from Clearpath Robotics which was modified to attach sensors along with a hub to mount drone during the DARPA Sub-T challenge.

DESIGN OF HASEL- SOFT ACTUATOR

Replicated as a part of soft machines class, HASEL (Hydraulically Amplified Self-healing ELectrostatic) actuator technology operates when electrostatic forces are applied to a flexible polymer pouch and dielectric liquid to drive shape change in a soft structure. These principles can be applied to achieve a contracting motion, expanding motion, or other complex deformations. HASEL actuator technology is electrically driven and couples electrostatic and hydraulic forces so a wide variety of actuation modes are possible.

VIRTUAL WAREHOUSE NAVIGATION ROBOT

Simulated robot and environment in Gazebo being able to localize itself and move through the map to the right object, then identify the object and validate the object to be picked and finally navigate itself to the drop-off location. Implemented Fast-SLAM, localized using Monte-Carlo localization method, and then navigated throughout the map with help of hybrid A* algorithm with an accuracy of 83%.

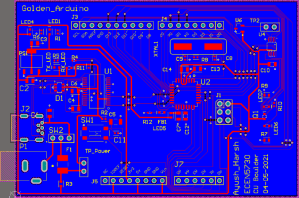

DESIGN OF MULTILAYER ARDUINO PCB

Designed a 4-Layer Arduino Uno PCB using Altium Designer tool; developed scope and performed circuit analysis. Implemented an FTDI-USB to UART interfacing chip Integrated an on-board Heartbeat and Temperature sensors using two digitally addressed LEDs (Neo-Pixel) & photodiode, interfaced through the I2C bus using a 16-bit ADC.

DESIGN OF MULTI-MATERIAL BEAM WITH GENETIC ALGORITHM

We developed a system of 3D-voxels by arranging mass-spring-dampers in a 3D coordinate system. Each unit voxel contained masses, one at each corner of the cube. Stacking one another, we obtained a mesh with 27 voxels and 64 masses altogether. Each unit voxel is formed with 12 spring-dampers aligned along the edge while four along the diagonals. While the properties of springs and dampers aligned along the sides were equal, the properties along diagonals were different. Hence, imparted a unique property to the voxel, and thus the behavior of composites was integrated into the system

Accu-Tube LLC.

Engineering Intern, Jun 2021 to Dec 2021

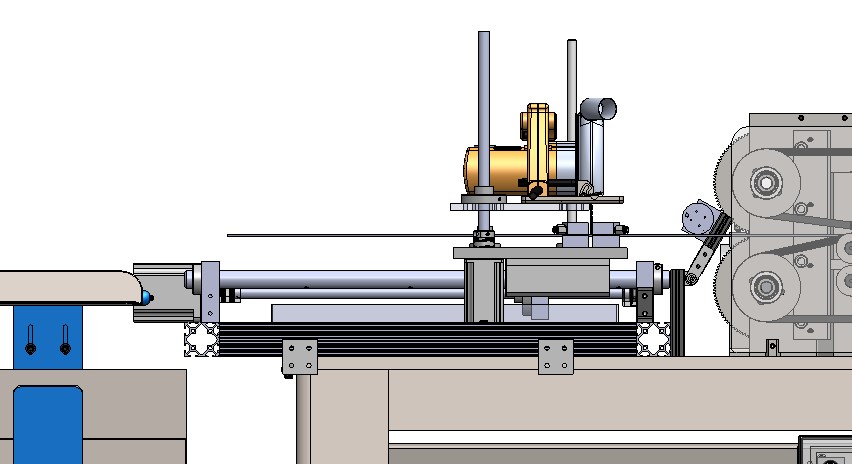

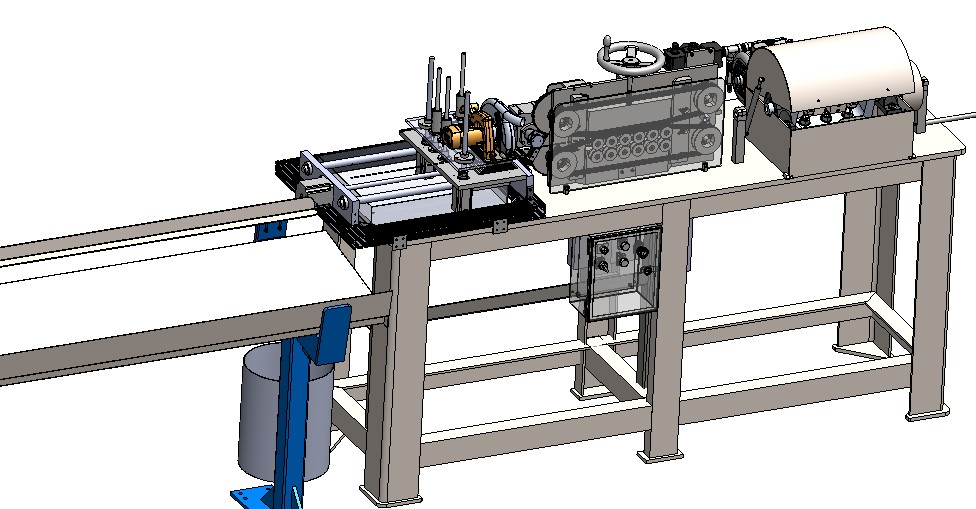

STRAIGHTENING FLYING CUT-OFF SAW

Produced an SPM to replace the shear operation on the straightening machine with a flying cutoff operation that leaves the ends of tubes open and does not leave burrs which used to be an operation after straightening where we cutoff the sheared ends of each tube. This creates additional scrap in the process and costs labor to run the saw operation. Complete removal of the manual cut operation from Accutube operations. There were 2600 hours of manual cut operations clocked during 2020. Elimination of this operation should reduce annual labor costs by ~$45,000. Additionally, we currently scrap ~3” of material per 12’ of material made. In 2020, we clocked 4,762,937 ft of shipped tubing. Assuming 12’ lengths for all that material, we shipped 396911 tubes. Given 3” of scrap/tube, that totals to 99,227 ft of tube scrapped due to this operation that will be eliminated with the addition of a flying cutoff saw. The average tube sells for $2.11/ft, therefore the scrap elimination would save ~$210,000/year.

Exponiq Engineering Services Pvt. Ltd.

CAD engineer, Jul 2018 to Jul 2019

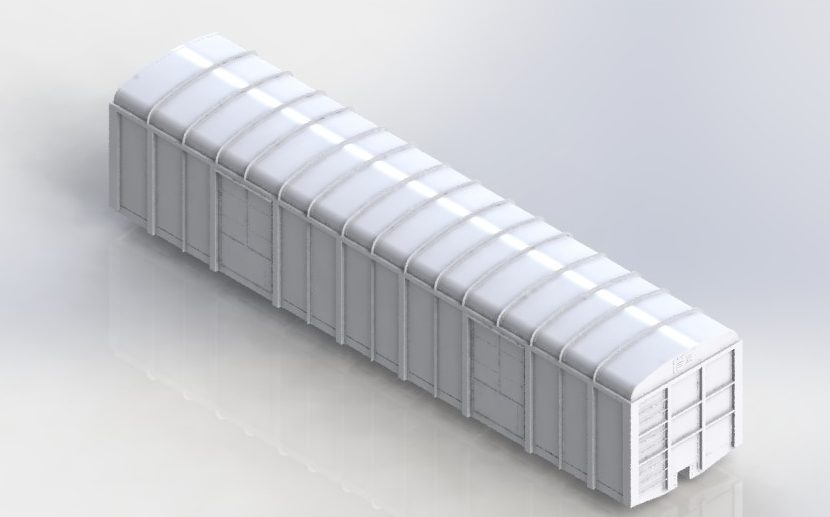

CLOSED RAILWAY FREIGHT WAGON

Closed railway wagon which was designed for moisture susceptible goods and has door arrangement to allow easy flow of material. The design and analysis were done to conform with the standards. Integrated mechanical, and pneumatic system design with components. Responsible for designing systems that met Indian Rail standards and customer requirements.

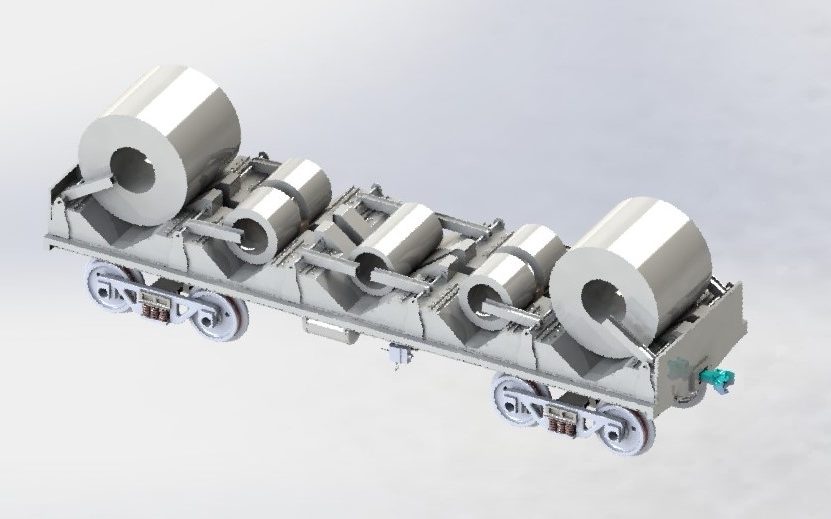

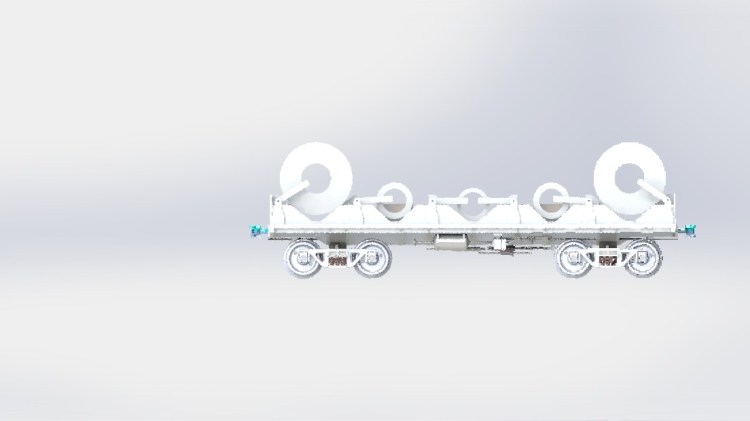

COIL WAGON TO CARRY SHEET METAL ROLLS

Railway wagons are designed to carry sheet rolls by using straps and the modular side barriers which sit on comb-like structures to be adjusted for different sizes of sheet metal rolls. The barriers can also be flipped 180 degrees to support bigger materials. The unique design is a replacement for the current open wagons which have been in use without any fixtures specially designed for metal rolls.

OPEN-TOPPED RAILWAY WAGON

The wagon is having similar dimensions to that of the closed wagon and is used for carrying coal and was designed with the same standards. The FEA was done to check the safety and fracture on the Gates and the critical components. The manufacturing drawings were also produced which were done with keeping in mind the manufacturing capabilities of the client.

VINTAGE THEME ELECTRIC VEHICLE

A 2 seater hatchback car based to look like a vintage car having an electric vehicle’s surface body was designed based on the current standards set by the government. The car’s body was made up of composite which were sheets of carbon fiber, so the car was designed to be manufactured using DFM principles so as to enable the easy pullout from the core.

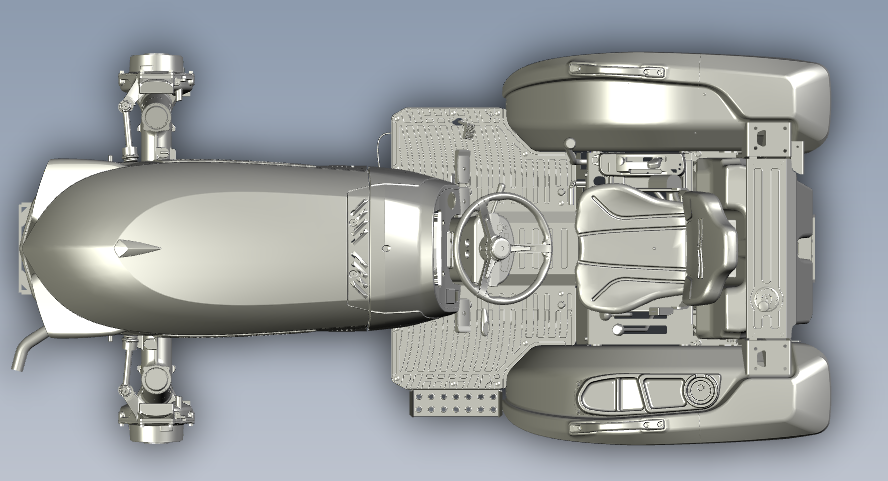

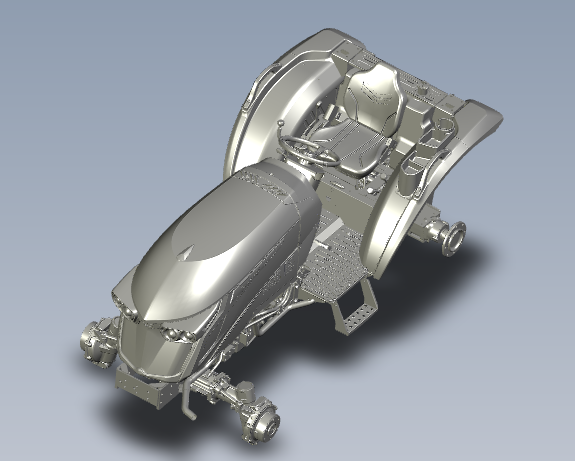

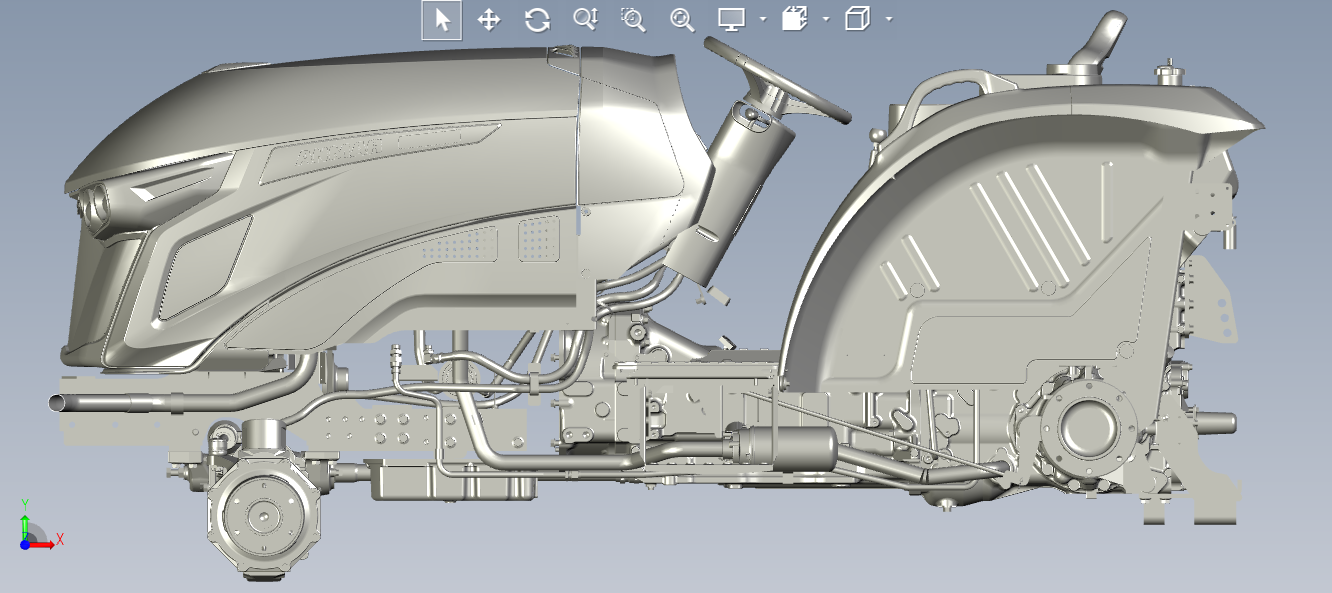

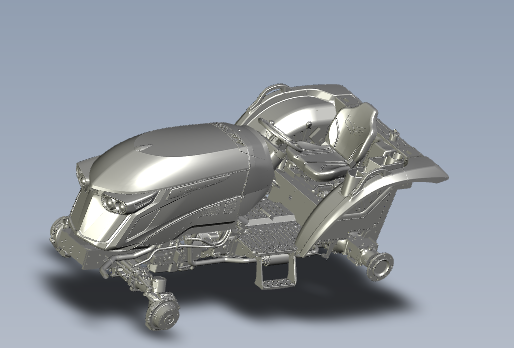

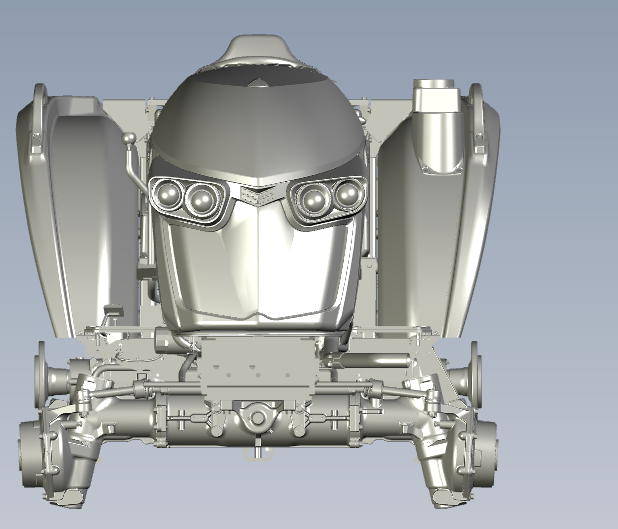

TRACTOR

The project consisted of designing a tractor’s sheet metal body and making the routing of the same. The routing included brake, exhaust, electrical, and transmission. Some off-the-shelf components were used for compatibility and interchangeability. This was a variant of the tractor that the client was already manufacturing but with some modifications in the hub.

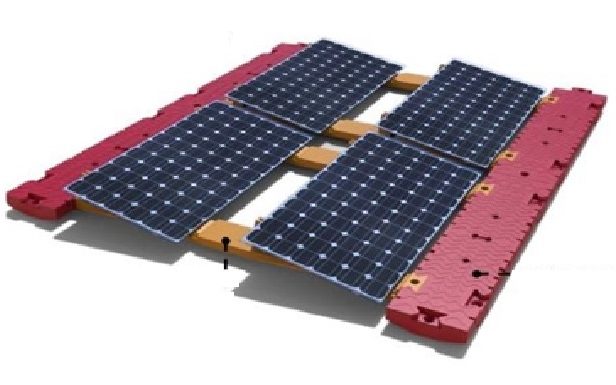

Yellow 2 Gen Energy Pvt. Ltd.

Mechanical Design engineer, Jan- Jul, 2018

JMoon Technologies Pvt. Ltd.

Mechanical Design Intern, Jan 2017 to Dec 2017

Project JJ

4 Wheel Omni Directional Robot-based useful for home automation using Raspberry Pi having PIR, Ultrasonic sensors, and a Camera for computer vision was designed and 3d printed using the in-house designed printer. There were multiple iterations and the final version is the one that can be seen on the left.

Animatronic Tail

The animatronic tail was made for a client as part of makerspace and was utilized in comic con. It was designed with 4 stepper motors with fish cable and the synchronized movement was utilized to mimic the motion intended.

Guru Gobind Singh Indraprastha University

Bachelor of Technology, AUG 2013 to MAY 2017

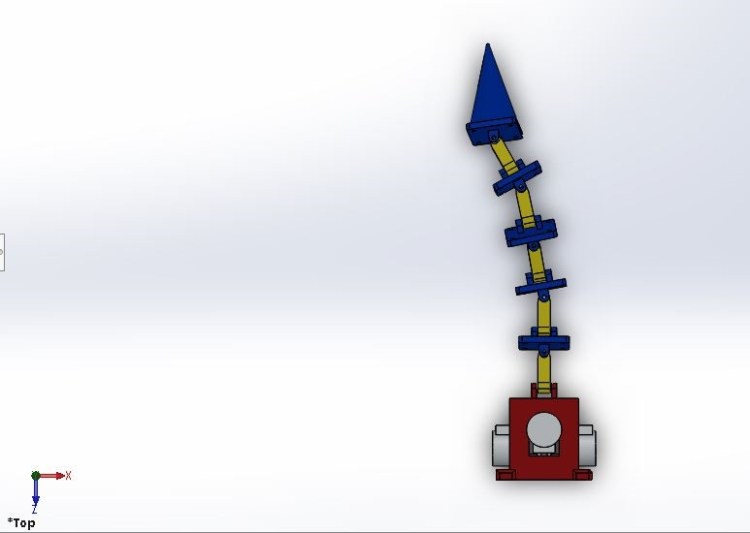

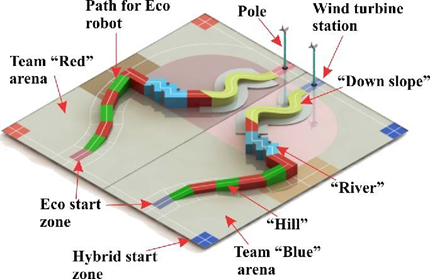

ROBOCON 2016- ASIA-PACIFIC ROBOTICS COMPETITION

The task was to build two robots; Eco Robot and Hybrid Robot. Hybrid Robot providing driving energy to Eco Robot to cross stages and had to take Wind Turbine Propeller from Eco Robot and climb up Wind Turbine Pole to assemble Wind Turbine. Involved in the design and fabrication of both the robots.

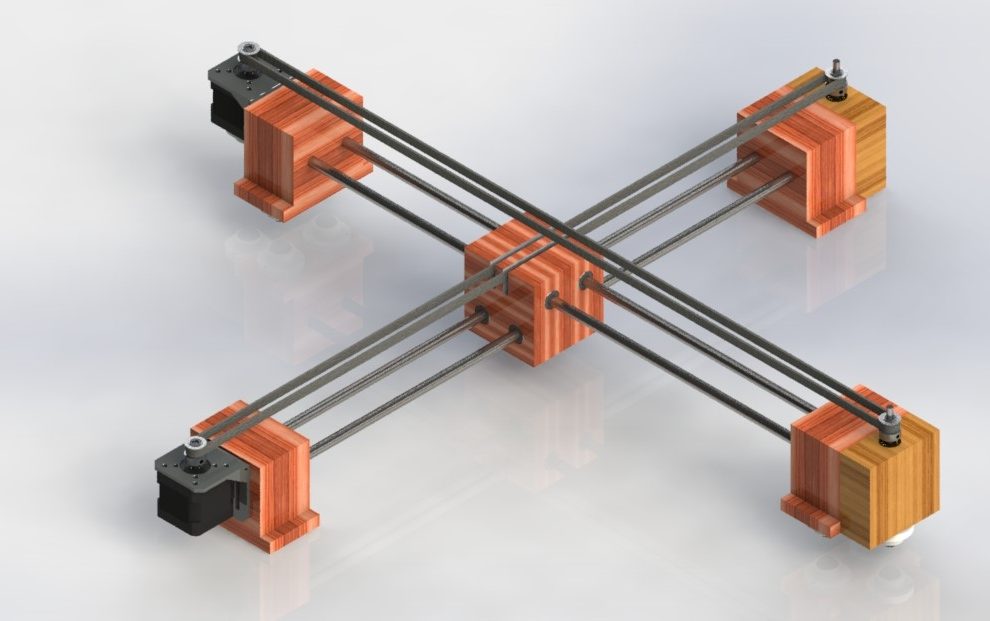

AUTOMATIC TRACKING WITH SCRIBBLING MECHANISM

Developed a scribbler that is intended to help blind people by writing their speech output with the help of a custom keyboard by using atmega16u2 and a tracking mechanism made using IR receiver and buzzer along with safety feature utilizing ultrasonic sensor and vibration motors.